A key issue for any FDM printer is bed adhesion; prints must be firmly attached to the bed during the print process to ensure they don’t move but they also need to be easy to remove without damage once the print is complete. There are countless bed surfaces, tapes, glues and tricks that printer manufacturers and printer operators use to achieve this combination of stickiness and removability and each method has their own fans and detractors. I’ve been looking for a good solution specifically for PETG/CPE printing as, for me, this is the material that causes the most grief.

PETG is unlike most FDM filaments in that it’s really too sticky. Print PETG directly onto glass or a PEI bed surface and you’re likely to find the finished part is forever welded to that surface. After some experimentation, I’d settled on using Scotch Blue Tape as the base for my PETG prints, sometimes combined with some Elmer’s Purple glue or 3DLac spray for particular models prone to first layer problems and/or warp. This method worked well in terms of adhesion, the parts stuck to the tape well, but was a pain for removal. To remove the model I had to soak the tape and the model in IPA (isopropyl alcohol) which would then usually allow the tape to come free from the bed with some “encouragement”, then soak the part further in water to remove any traces of tape still stuck onto the part itself. This worked OK but was messy and time-consuming both on removal and in preparing the bed for printing initially. So, I was keen to find a print surface that would make my PETG printing easier.

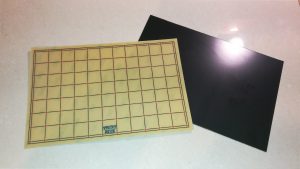

I can’t remember where I first saw PrintBite mentioned, but the reviews suggested it could be exactly what I was looking for. Allegedly the PrintBite surface would keep parts secure while printing but also allows them to be simply lifted away once the bed was cool. As a plus, the bottom surface would be smooth and glossy. When I knew I had a large order for PETG coming up, and one that would benefit from that smooth lower surface, I took the plunge and ordered a PrintBite sheet cut for my FlashForge Pro. So, does it work?

The answer is a clear YES, but there are some caveats…

It seems clear that it’s vital you follow the fitting instructions. Fitting the sheet physically is very similar to fitting any other bed surface by removing a backing sheet slowly as you smooth the surface down onto your bed, but there’s then a curing process to go through that involves damp cloths and cycling the bed temperature up and down a couple of times over two hours. Once this is done you will need to adjust your z-height setting and your bed temperature for the material you want to use. PrintBite doesn’t need the material squished onto the bed as much as other surfaces and you’ll likely need to raise the bed temperature 10C or maybe more – I print now at 85C first 3 layers and 80C for the remainder for PETG.

My first print after this tuning and fiddling really did exactly what it said on the tin. The part remained locked to the surface during the print then, once I’d let the bed cool below 40C or so, simply lifted free. It really was quite a revelation. No tape, no glue, no mess and a lovely smooth lower surface. Hurrah! The next couple of prints were exactly the same, but the fourth failed horribly. On the fourth print, the first layer simply didn’t stick to the surface at all, it was as though the nozzle was way too high (so much so my first check was to check the bed calibration). Looking at the surface itself it seemed there was some residue from the previous prints so I wiped it clean with acetone (I’d read the instructions that say you must not use IPA, as you would with a PEI sheet). Tried again and it the model printed fine, which was great until I came to remove it. Even cooled right down to room temperature, the model was still firmly fixed to the bed. Fortunately, it was a small model and I was able to remove it by careful use of my usual scraper, but left behind was a single layer of PETG still firmly fixed to the bed. It looked like, somehow, I’d managed to ruin the surface after only having it fitted for a day. I attacked the residue with the scraper and it came away slowly, and, much to my surprise, left the surface apparently completely undamaged. I then read the instructions again and read the part that says the bed should be cleaned with soapy water, not any kind of chemical. So I’m chalking that one up to my own stupidity.

I’ve now completed about 15 successful prints and it really does seem to work as it should. I have had a couple of failures, one where the part came free of the bed about 5 minutes from the end of a 6 hour print, and one where the part stayed attached but had warped away from the bed on one side, but I’m pretty sure they were due to a combination of bed cleanliness (I wasn’t always cleaning the bed after each print) and probably the bed being 5C too cool – particularly as these failures happened on a relatively cold night.

Would I recommend it? Without hesitation, as long as you read the instructions fully and completely and take the time needed to dial in your print settings. That said, I’ve only tested the surface with PETG and CPE from Fillamentum and I have seen comments online that suggest there are problems with other filaments/materials. For me, this isn’t a concern since I only really use the FlashForge for PETG/CPE and I have spare glass beds I can swap out anyway.

It’s not cheap, but it’s not really that much more than a sheet of PEI, and it is so wonderful to just lift a clean, smooth print away that it’s well worth that little extra.

Get your PrintBite+ surface here from Flex3Drive